-

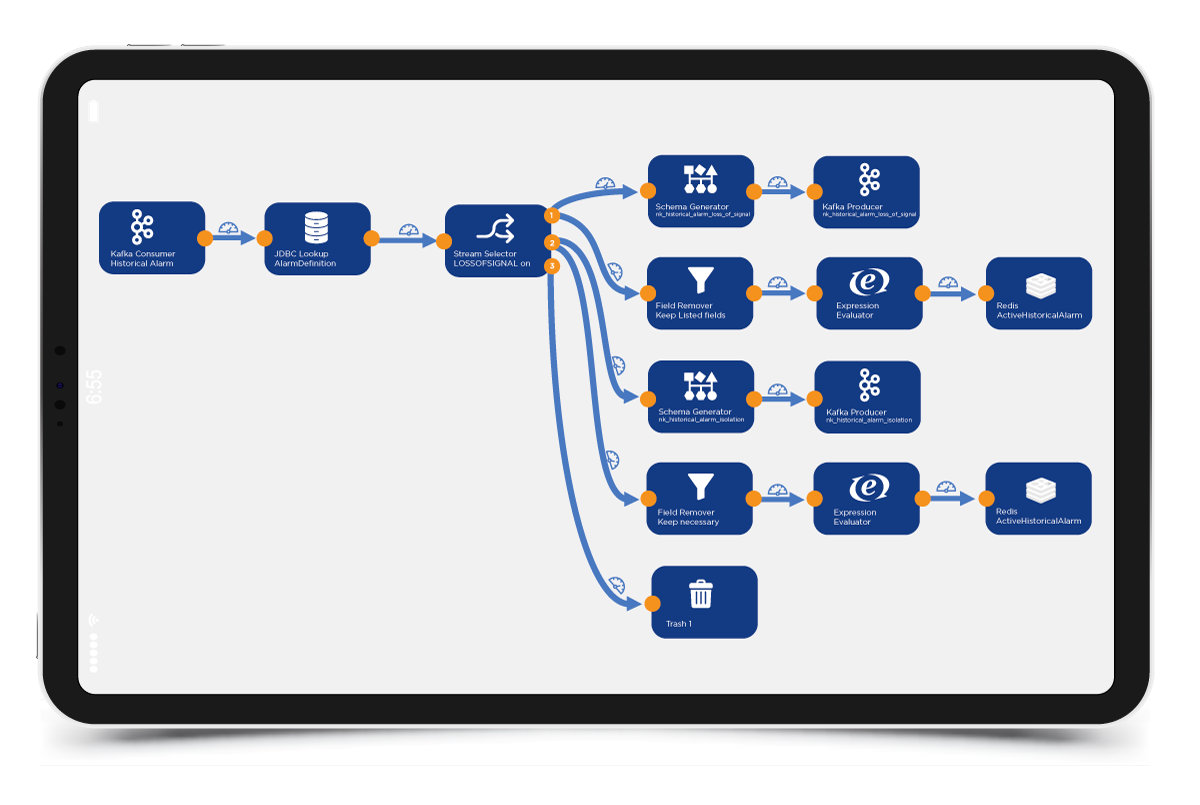

Instant Information – Extraction, transformation and loading of data as continuous flows on demand.

- Continuous Operation – Seamless and fault tolerant.

- Visible Data Flows – Graphical implementation of processes.

- Unification – Multiple sources and data types towards a constant and continuous data delivery.

- Hierarchical Control – Different projects with independent use of resources by different areas, business units or departments.

- Open Source

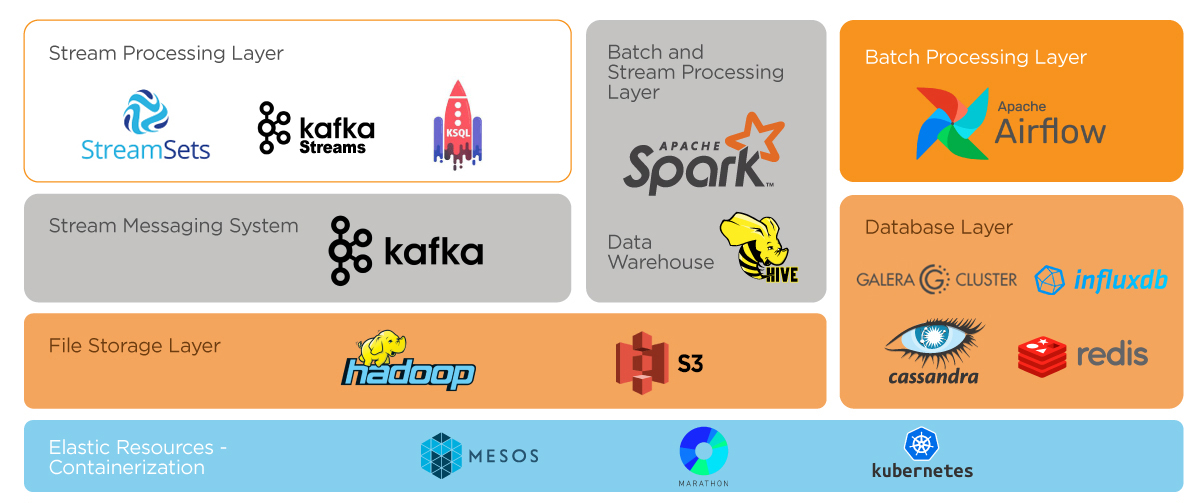

Data Engineering Platforms

We deploy platforms to deliver continuos information. Connecting to any source, regardless of the variety or structure of the data, we answer business questions at high speed with technologies that allow us to scale horizontally.

We operate clusters that provides unmatched resiliency, guaranteeing operational continuity at all levels using open source software.

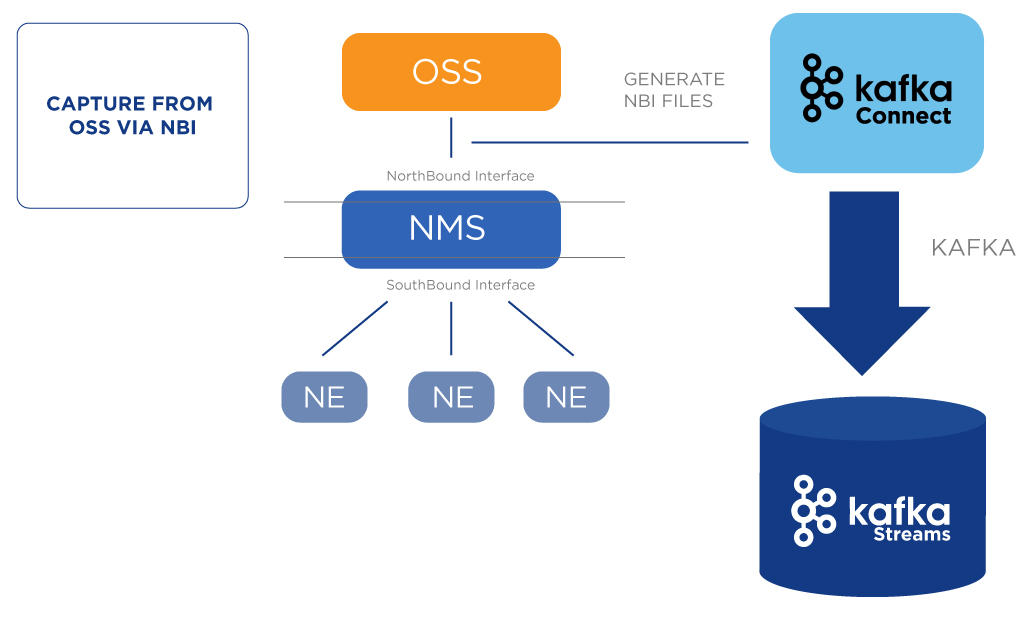

Network-Element Agnostic

- Standard integration via NBI to OSS and BSS or proprietary connectors.

- Multi-vendor support (U2000, Nokia NetAct, etc).

- Radius / Diameter / SNMP Traps integration.

- Extraction from different Access components (RAN-EPC / EPS, OLT, OMS).

Engineered for Operational Continuity

- Elastic, resilent and fault tolerant.

- Highly available storage.

- Ability to detect and handle data drift.

- Containerized.

- Ideal to deploy analytical solutions.

- Simple and easy to use.

Network Performance Indicators

- Near real-time monitoring (given by the OSS data exposure rate) capturing the data via NBI, being able to visualize the state of the network as a continuous information flow.

- Historical reports on demand through distributed processing.

Fiber optic massive failures detection

- Complex streaming logic application to detect faults through combinations of OSS alarms.

- By shortening detection, repair times are improved increasing the quality of service, which is measured and displayed in the same platform.

- Clearly knowing about the problem and state of the failures, unnecessary technical visits are reduced and accurate information can be delivered to the affected customers.

Preventative Maintenance Priorization for RAN (cell sites)

- Detection of potential failures before they occur, helping to prioritize maintenance.

- It makes possible to improve the quality of service and customer perception.

- Allow to optimize routes, resources and operations.

Contacto

Av. Las Condes 7700 – Of 405 A, Las Condes, Región Metropolitana, Chile

+56 (2) 2321 3095

info@qin.cl